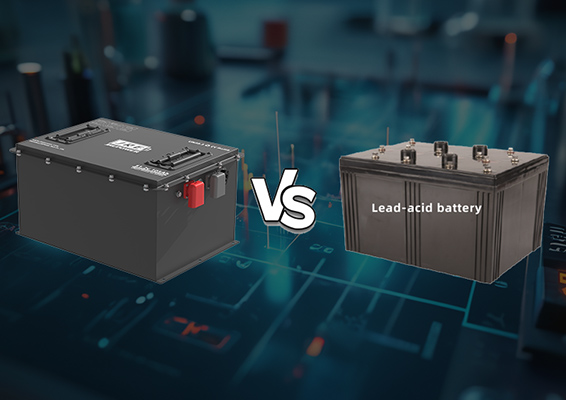

JREPower Golf Cart Battery

Six advantages of Golf Cart Battery

Zero-Voltage Recharge capability

Longer runtime per charge compared to lead-acid batteries.

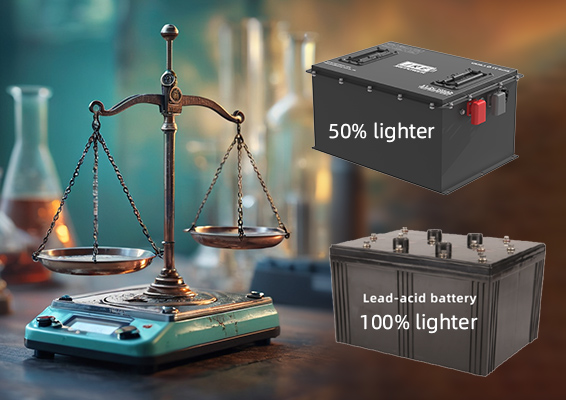

Lightweight Design

50% lighter, improving cart efficiency and maneuverability.

Fast Charging

80% charge in 2 hours, minimizing downtime.

Extended Lifespan

5,000+ cycles, 3x longer than traditional batteries.

Eco-Friendly:

Zero emissions, recyclable materials.

Smart BMS

Overcharge/discharge protection, temperature monitoring.

JREPower Golf Cart Battery

Common applications

Case

A scenic resort currently has 160 golf carts, all of which are equipped with traditional lead-acid batteries. A single charge can provide a range of approximately 50 to 60 kilometers, meeting the daily basic operational needs.

challenge

Operation process: It requires centralized charging for 8 to 10 hours every day, with dedicated personnel for maintenance (adding water, cleaning, and regular equalization charging). The battery life is approximately 1.5 to 2 years and needs to be replaced.

Cost proportion: The cost of battery procurement and maintenance accounts for 35% to 40% of the total operating cost of the golf cart.

Insufficient battery range: During peak season and high-load operation, the battery range drops to 30-40 kilometers, requiring mid-journey recharging, which affects the efficiency of vehicle dispatching.

After using JREpower lithium batteries

Battery life doubling: At the same voltage, the energy density of lithium batteries is increased by 2 to 3 times, and the battery life is extended to 100 to 120 kilometers, easily covering all-day operation.

Fast charging support: Compatible with 1-3 hour fast charging technology (supporting 80% battery charge within 1 hour), midday recharge can meet the peak demand in the afternoon.

Maintenance-free design: Fully sealed structure, no need to add water or clean, reducing daily maintenance workload by 90%.

Zero-pollution commitment: Lead-free, acid-free, and the production and scrapping processes comply with RoHS environmental protection standards.

Intelligent upgrade: Integrate the BMS system to monitor battery health in real time and locate vehicles, enhancing management efficiency.

Brand empowerment: The concept of “all-lithium battery Green Resort” can be promoted, which aligns with the sustainable development preferences of high-end customers.

JREPower energy storage-related products

Why choose JREPower sodium ion starter battery

More scientific internal

structural design

JREPower sodium battery cells are fixed with a supportto avoid damage to the internal structure of the batterycaused by vibration during use.

Long design life an

dcycle life

JREPower sodium battery has a design life of 10 years and 3000 cycle times.

Perfect quality

assurance service

JREPower sodium battery cells are fixed with a supportto avoid damage to the internal structure of the batterycaused by vibration during use.

OEM& ODM

Customization

JREPower sodium battery has a design life of 10 years and 3000 cycle times.

Mass production service process

When the customer starts the bulk order, we will enter the mass production service process.

1. Planning

Video conference/teleconference to communicate batteryproduktion plan.

2.Plan verification

Email to confirm the details of the plan, battery productionquantity,production requirements, delivery time, transpor-tation terms and other information.

3.Prqcurement ofraw materials

After the customer pays the advance payment, the JRE pro.curement department determines the type, specificationsand quantity of raw materials required according to the pro-duction plan, negotiates with the supplier and purchases.

4.Production preparation

The jRE account manager makes production schedule andquality inspection specifications based on different productcustomization requirements, and submits them to the JREproduction supervisor and jRE qualityinspection engineer.

5. Battery production

The jRE production supervisor shall formulate productioninstructions according to the requirements of the jREaccount manager, and the workers shall carry out produc-tion according to the production instructions to ensure thatthe products meet the quality requirements.

6. Quality control

During the product production process, jRE production linequality inspection engineers supervise the product produc-tion process according to the qualityinspection specifica-tions and production instructions, and check whether eachproduct detail meets the quality inspection requirements,

7.Progress tracking

The jRE account manager tracks the battery productionprogress and reports it to the customer.

8.Warehousing offinished products

Warehousing management of qualified products, includingidentification, storage and other operations, to ensure thatproducts are not damaged or contaminated.

9.Packaging and marking

Packaging the finished product, and according to therequirements of identification, labeling, numbering, etc., tofacilitate sales and logistics.

10.Product delivery

After comprehensive inspection of finished products, factorydelivery and delivery are arranged according to the transaction requirements agreed on in the order.

51.2V 105Ah LFP LiFePo4 Golf cart battery JREPower JRE battery

5376Wh JszG-LF2790